<b>Ballast Water Treatment Systems (BWTS) </b>

Originally all ships would have had a BWTS installed on board by September 2022. But shipowners successfully obtained a delay for existing vessels and thus have more time to install treatment systems on board. Now operators/owners have to implement the facilities until the final deadline in September 2024. The new Ballast Water Management Convention has a massive impact on the shipping sector worldwide. The investment for one BWTS can be up to 2 Mill. €.

There are a wide variety of treatment options for ballast water treatment systems:

<b>ELECTROLYSIS</b> Electrolysis systems run all or part of the ballast water through electrolysis chambers which generate an active substance (a disinfectant) that breaks down the cell membranes of aquatic organisms. With inline electrolysis systems, the entire ballast stream is passed through electrolysis chambers. Side stream electrolysis systems may combine electrolysis with a filter, where a small portion of ballast water flow is led through the electrolysis chamber where disinfectants are generated and returned to the main ballast flow.

<b>UV</b> UV systems generally utilize filters and ultraviolet light (UV). UV light kills or inactivates organisms by disrupting their DNA, leaving them unable to perform vital cellular functions. UV systems do not form any harmful by-products, and the process is principally independent of the temperature and salinity (however, the UV transmit¬tance is not). The process may have relatively high energy demand in such cases. The efficiency of systems using UV light depends on total suspended solids (TSS) and the opacity of the water. UV systems do not form any harmful by-products, and the process is principally independent of the temperature and salinity (however, the UV transmittance is not). The process may have relatively high energy demand in such cases.

<b>OZONATION</b> Ozonation systems generate ozone (03) from ambient air. Ozone is injected into the incoming ballast water to oxidize and neutralize aquatic species. Ozone reacts with other chemicals that occur naturally in seawater to form hypobromous acid and hypobromide ion. These are effective disinfectants. Where ships take on fresh water as ballast (e.g. in ports located in lakes or rivers), brominated compounds are not formed and the ozone alone acts as disinfectant. Waters with high particulate and organic matter require higher doses of ozone to ensure sufficient disinfection. Salinity and temperature are not obvious factors affecting the efficiency of BWTS employing ozonation.

<b>CHEMICAL INJECTION</b> Chemical injection systems are often used in combination with filtration. A chemical solution is injected into the ballast water to ensure disinfection. The disinfectant may be liquid or granular and is often similar to the disinfectant used in domestic water treatment plants. Chemicals may successfully treat ballast water under various conditions and are not affected by salinity of the ballast water. Some systems require neutralization prior to discharge. The chemicals must be stored on board in closed containers and are highly toxic. Hence, the use of chemicals requires implementation of strict safety provisions and crew training. Due to chemicals supply, chemical injection systems may have higher operational costs than other systems utilizing other technologies. Cavitation Ultrasonic energy is used to produce high-energy ultrasound to kill the cells of the organisms in ballast water. Such high pressure ballast water cavitation techniques are generally used in combination with other technologies. Ballast water treatment systems may combine cavitation with filtration, UV, ozone or deoxygenation.

<b>DEOXYGENATION</b> Deoxygenation may be used in combination with other technologies such as cavitation or pasteurization. This treatment method involves stripping of oxygen from the ballast water to suffocate organisms. This is usually done by injecting nitrogen or another inert gas in to the ballast water. The low oxygen level then kills most of the oxygen-dependent organisms. It generally takes several days for the inert gas to fully deoxygenate the water. Hence, this method is usually not suitable for ships having short transit time. If a ship is already installed with an inert gas system, then a deoxygenation system will not require more space on board ships.

The various BWTS technologies may face challenges in specific water conditions, and approval certificate guarantee treatment of all types of water in line with the D-2 standard: "Approval of a system, however, does not ensure that a given system will work on all vessels or in all situations". In case of doubt regarding treatment performance of the given water, or if the system fails during ballast intake, sequential water exchange with treatment when out of port may be an option. Sequential water exchange will work as a back-up plan. However, once the IMO Convention enters into force and D-2 compliance is compulsory, shipowners will need to notify the port state if they need to perform sequential exchange, and the port state will need to accept this as a solution.

<b>Ballast Water Treatment Systems (BWTS) </b>

Originally all ships would have had a BWTS installed on board by September 2022. But shipowners successfully obtained a delay for existing vessels and thus have more time to install treatment systems on board. Now operators/owners have to implement the facilities until the final deadline in September 2024. The new Ballast Water Management Convention has a massive impact on the shipping sector worldwide. The investment for one BWTS can be up to 2 Mill. €.

There are a wide variety of treatment options for ballast water treatment systems:

<b>ELECTROLYSIS</b> Electrolysis systems run all or part of the ballast water through electrolysis chambers which generate an active substance (a disinfectant) that breaks down the cell membranes of aquatic organisms. With inline electrolysis systems, the entire ballast stream is passed through electrolysis chambers. Side stream electrolysis systems may combine electrolysis with a filter, where a small portion of ballast water flow is led through the electrolysis chamber where disinfectants are generated and returned to the main ballast flow.

<b>UV</b> UV systems generally utilize filters and ultraviolet light (UV). UV light kills or inactivates organisms by disrupting their DNA, leaving them unable to perform vital cellular functions. UV systems do not form any harmful by-products, and the process is principally independent of the temperature and salinity (however, the UV transmit¬tance is not). The process may have relatively high energy demand in such cases. The efficiency of systems using UV light depends on total suspended solids (TSS) and the opacity of the water. UV systems do not form any harmful by-products, and the process is principally independent of the temperature and salinity (however, the UV transmittance is not). The process may have relatively high energy demand in such cases.

<b>OZONATION</b> Ozonation systems generate ozone (03) from ambient air. Ozone is injected into the incoming ballast water to oxidize and neutralize aquatic species. Ozone reacts with other chemicals that occur naturally in seawater to form hypobromous acid and hypobromide ion. These are effective disinfectants. Where ships take on fresh water as ballast (e.g. in ports located in lakes or rivers), brominated compounds are not formed and the ozone alone acts as disinfectant. Waters with high particulate and organic matter require higher doses of ozone to ensure sufficient disinfection. Salinity and temperature are not obvious factors affecting the efficiency of BWTS employing ozonation.

<b>CHEMICAL INJECTION</b> Chemical injection systems are often used in combination with filtration. A chemical solution is injected into the ballast water to ensure disinfection. The disinfectant may be liquid or granular and is often similar to the disinfectant used in domestic water treatment plants. Chemicals may successfully treat ballast water under various conditions and are not affected by salinity of the ballast water. Some systems require neutralization prior to discharge. The chemicals must be stored on board in closed containers and are highly toxic. Hence, the use of chemicals requires implementation of strict safety provisions and crew training. Due to chemicals supply, chemical injection systems may have higher operational costs than other systems utilizing other technologies. Cavitation Ultrasonic energy is used to produce high-energy ultrasound to kill the cells of the organisms in ballast water. Such high pressure ballast water cavitation techniques are generally used in combination with other technologies. Ballast water treatment systems may combine cavitation with filtration, UV, ozone or deoxygenation.

<b>DEOXYGENATION</b> Deoxygenation may be used in combination with other technologies such as cavitation or pasteurization. This treatment method involves stripping of oxygen from the ballast water to suffocate organisms. This is usually done by injecting nitrogen or another inert gas in to the ballast water. The low oxygen level then kills most of the oxygen-dependent organisms. It generally takes several days for the inert gas to fully deoxygenate the water. Hence, this method is usually not suitable for ships having short transit time. If a ship is already installed with an inert gas system, then a deoxygenation system will not require more space on board ships.

The various BWTS technologies may face challenges in specific water conditions, and approval certificate guarantee treatment of all types of water in line with the D-2 standard: "Approval of a system, however, does not ensure that a given system will work on all vessels or in all situations". In case of doubt regarding treatment performance of the given water, or if the system fails during ballast intake, sequential water exchange with treatment when out of port may be an option. Sequential water exchange will work as a back-up plan. However, once the IMO Convention enters into force and D-2 compliance is compulsory, shipowners will need to notify the port state if they need to perform sequential exchange, and the port state will need to accept this as a solution.

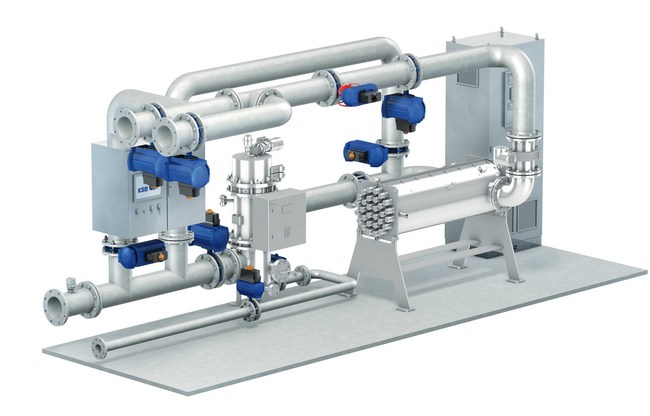

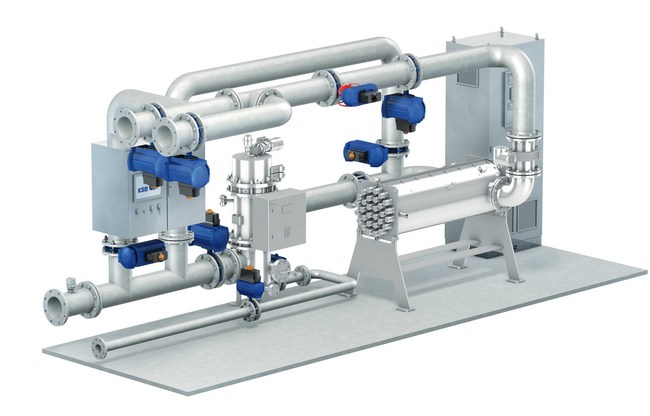

Ballast Water Treatment System

<b>Ballast Water Treatment Systems (BWTS) </b>

Originally all ships would have had a BWTS installed on board by September 2022. But shipowners successfully obtained a delay for existing vessels and thus have more time to install treatment systems on board. Now operators/owners have to implement the facilities until the final deadline in September 2024. The new Ballast Water Management Convention has a massive impact on the shipping sector worldwide. The investment for one BWTS can be up to 2 Mill. €.

There are a wide variety of treatment options for ballast water treatment systems:

<b>ELECTROLYSIS</b> Electrolysis systems run all or part of the ballast water through electrolysis chambers which generate an active substance (a disinfectant) that breaks down the cell membranes of aquatic organisms. With inline electrolysis systems, the entire ballast stream is passed through electrolysis chambers. Side stream electrolysis systems may combine electrolysis with a filter, where a small portion of ballast water flow is led through the electrolysis chamber where disinfectants are generated and returned to the main ballast flow.

<b>UV</b> UV systems generally utilize filters and ultraviolet light (UV). UV light kills or inactivates organisms by disrupting their DNA, leaving them unable to perform vital cellular functions. UV systems do not form any harmful by-products, and the process is principally independent of the temperature and salinity (however, the UV transmit¬tance is not). The process may have relatively high energy demand in such cases. The efficiency of systems using UV light depends on total suspended solids (TSS) and the opacity of the water. UV systems do not form any harmful by-products, and the process is principally independent of the temperature and salinity (however, the UV transmittance is not). The process may have relatively high energy demand in such cases.

<b>OZONATION</b> Ozonation systems generate ozone (03) from ambient air. Ozone is injected into the incoming ballast water to oxidize and neutralize aquatic species. Ozone reacts with other chemicals that occur naturally in seawater to form hypobromous acid and hypobromide ion. These are effective disinfectants. Where ships take on fresh water as ballast (e.g. in ports located in lakes or rivers), brominated compounds are not formed and the ozone alone acts as disinfectant. Waters with high particulate and organic matter require higher doses of ozone to ensure sufficient disinfection. Salinity and temperature are not obvious factors affecting the efficiency of BWTS employing ozonation.

<b>CHEMICAL INJECTION</b> Chemical injection systems are often used in combination with filtration. A chemical solution is injected into the ballast water to ensure disinfection. The disinfectant may be liquid or granular and is often similar to the disinfectant used in domestic water treatment plants. Chemicals may successfully treat ballast water under various conditions and are not affected by salinity of the ballast water. Some systems require neutralization prior to discharge. The chemicals must be stored on board in closed containers and are highly toxic. Hence, the use of chemicals requires implementation of strict safety provisions and crew training. Due to chemicals supply, chemical injection systems may have higher operational costs than other systems utilizing other technologies. Cavitation Ultrasonic energy is used to produce high-energy ultrasound to kill the cells of the organisms in ballast water. Such high pressure ballast water cavitation techniques are generally used in combination with other technologies. Ballast water treatment systems may combine cavitation with filtration, UV, ozone or deoxygenation.

<b>DEOXYGENATION</b> Deoxygenation may be used in combination with other technologies such as cavitation or pasteurization. This treatment method involves stripping of oxygen from the ballast water to suffocate organisms. This is usually done by injecting nitrogen or another inert gas in to the ballast water. The low oxygen level then kills most of the oxygen-dependent organisms. It generally takes several days for the inert gas to fully deoxygenate the water. Hence, this method is usually not suitable for ships having short transit time. If a ship is already installed with an inert gas system, then a deoxygenation system will not require more space on board ships.

The various BWTS technologies may face challenges in specific water conditions, and approval certificate guarantee treatment of all types of water in line with the D-2 standard: "Approval of a system, however, does not ensure that a given system will work on all vessels or in all situations". In case of doubt regarding treatment performance of the given water, or if the system fails during ballast intake, sequential water exchange with treatment when out of port may be an option. Sequential water exchange will work as a back-up plan. However, once the IMO Convention enters into force and D-2 compliance is compulsory, shipowners will need to notify the port state if they need to perform sequential exchange, and the port state will need to accept this as a solution.

<b>Ballast Water Treatment Systems (BWTS) </b>

Originally all ships would have had a BWTS installed on board by September 2022. But shipowners successfully obtained a delay for existing vessels and thus have more time to install treatment systems on board. Now operators/owners have to implement the facilities until the final deadline in September 2024. The new Ballast Water Management Convention has a massive impact on the shipping sector worldwide. The investment for one BWTS can be up to 2 Mill. €.

There are a wide variety of treatment options for ballast water treatment systems:

<b>ELECTROLYSIS</b> Electrolysis systems run all or part of the ballast water through electrolysis chambers which generate an active substance (a disinfectant) that breaks down the cell membranes of aquatic organisms. With inline electrolysis systems, the entire ballast stream is passed through electrolysis chambers. Side stream electrolysis systems may combine electrolysis with a filter, where a small portion of ballast water flow is led through the electrolysis chamber where disinfectants are generated and returned to the main ballast flow.

<b>UV</b> UV systems generally utilize filters and ultraviolet light (UV). UV light kills or inactivates organisms by disrupting their DNA, leaving them unable to perform vital cellular functions. UV systems do not form any harmful by-products, and the process is principally independent of the temperature and salinity (however, the UV transmit¬tance is not). The process may have relatively high energy demand in such cases. The efficiency of systems using UV light depends on total suspended solids (TSS) and the opacity of the water. UV systems do not form any harmful by-products, and the process is principally independent of the temperature and salinity (however, the UV transmittance is not). The process may have relatively high energy demand in such cases.

<b>OZONATION</b> Ozonation systems generate ozone (03) from ambient air. Ozone is injected into the incoming ballast water to oxidize and neutralize aquatic species. Ozone reacts with other chemicals that occur naturally in seawater to form hypobromous acid and hypobromide ion. These are effective disinfectants. Where ships take on fresh water as ballast (e.g. in ports located in lakes or rivers), brominated compounds are not formed and the ozone alone acts as disinfectant. Waters with high particulate and organic matter require higher doses of ozone to ensure sufficient disinfection. Salinity and temperature are not obvious factors affecting the efficiency of BWTS employing ozonation.

<b>CHEMICAL INJECTION</b> Chemical injection systems are often used in combination with filtration. A chemical solution is injected into the ballast water to ensure disinfection. The disinfectant may be liquid or granular and is often similar to the disinfectant used in domestic water treatment plants. Chemicals may successfully treat ballast water under various conditions and are not affected by salinity of the ballast water. Some systems require neutralization prior to discharge. The chemicals must be stored on board in closed containers and are highly toxic. Hence, the use of chemicals requires implementation of strict safety provisions and crew training. Due to chemicals supply, chemical injection systems may have higher operational costs than other systems utilizing other technologies. Cavitation Ultrasonic energy is used to produce high-energy ultrasound to kill the cells of the organisms in ballast water. Such high pressure ballast water cavitation techniques are generally used in combination with other technologies. Ballast water treatment systems may combine cavitation with filtration, UV, ozone or deoxygenation.

<b>DEOXYGENATION</b> Deoxygenation may be used in combination with other technologies such as cavitation or pasteurization. This treatment method involves stripping of oxygen from the ballast water to suffocate organisms. This is usually done by injecting nitrogen or another inert gas in to the ballast water. The low oxygen level then kills most of the oxygen-dependent organisms. It generally takes several days for the inert gas to fully deoxygenate the water. Hence, this method is usually not suitable for ships having short transit time. If a ship is already installed with an inert gas system, then a deoxygenation system will not require more space on board ships.

The various BWTS technologies may face challenges in specific water conditions, and approval certificate guarantee treatment of all types of water in line with the D-2 standard: "Approval of a system, however, does not ensure that a given system will work on all vessels or in all situations". In case of doubt regarding treatment performance of the given water, or if the system fails during ballast intake, sequential water exchange with treatment when out of port may be an option. Sequential water exchange will work as a back-up plan. However, once the IMO Convention enters into force and D-2 compliance is compulsory, shipowners will need to notify the port state if they need to perform sequential exchange, and the port state will need to accept this as a solution.